Zenit-3SL – Launch Vehicle

The Zenit 3SL Launch Vehicle is an expendable carrier rocket that is part of the Zenit Rocket Family. Zenit 3SL is operated by Sea Launch, California – a company owned by RSC Energia (40%), Boeing (25%), Aker Solutions (20%) and Yuzhnoye (15%). The Rocket was designed by the Yuzhnoye Design Bureau and is constructed by Yuzhmash, both Ukraine.

It is a two stag rocket that is outfitted with a modified Block-DM Upper Stage built by RSC Energia. The Payload Fairing of the vehicle is provided by Boeing. Development of the Zenit 3 Rocket Family began back in 1980 for two purposes. Its first stage was intended as booster for the Energia launch vehicle, and equipped with a second stage, the vehicle was designed as an independent launcher.

Zenit 3SL made its maiden flight in 1999 while the SLB version first flew in 2008. Since then, 35 launches of the 3SL version have taken place to date with three failures and one partial failure. Land Launch has flown five Zenit Missions – all successful.

Sea Launch integrates the Launch Vehicle at its Home Port in California, USA. Then, the launcher is moved to the launch site located in the Pacific Ocean. Zenit 3SL is launched from the Odyssey Launch Platform that is located at 0 Degrees North and 154 Degrees West. This position was selected based on several factors, including stage impact zones, weather, and vessel transit times.

Zenit-3SL Specifications

| Type | Zenit-3SL |

| Height | 58.65m |

| Diameter | 3.9m |

| Launch Mass | 465,800kg |

| Stages | 3 |

| Stage 1 | Zenit 2 First Stage |

| Stage 2 | Zenit 2 Second Stage |

| Upper Stage | Block DM-SL |

| Mass to LEO | 13,500kg |

| Mass to MEO | 5,700kg |

| Mass to GTO | 6,060kg |

| Mass to GEO | 3,600kg |

The Zenit-3SL Vehicle consists of the basic two-stage Zenit 2 design with two lower stages fueled by Liquid Oxygen and Kerosene. The two integrated stages are 43.3 meters long and 4.1 meters in diameter. Atop the second stage, the Block DM-SL Upper Stage is installed which is based on the Block-DM Upper Stage which in turn is a modification of the historic Block-D. The launch vehicle is topped by a 4.15-meter diameter Payload Fairing.

Major configuration improvements have been made distinguishing the Zenit-3SL Vehicle from its predecessors, namely the Zenit-2. These modifications include new avionics, navigation computers as well as mass reductions and structural improvements.

Zenit-3SLB stands 59.65 meters high and has a diameter of 3.9 meters.

In its 3SL configuration, the vehicle is almost exclusively used for launches to Geostationary Transfer Orbit to which it can carry payloads of up to 6,060 Kilograms.

First Stage

| Type | Zenit 2 First Stage |

| Length | 32.9m |

| Diameter | 3.9m |

| Inert Mass | 27,564kg |

| Launch Mass/Fueled | 354,350kg |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| Fuel Mass | 90,219kg |

| Oxidizer Mass | 236,567kg |

| Material | Aluminum, Stiffeners |

| Guidance | From 2nd Stage |

| Propulsion | 1 RD-171 |

| Engine Type | Staged Combustion |

| Propellant Feed | Turbopump |

| Comb. Chambers | 4 |

| Total Thrust SL | 7.550MN |

| Total Thrust Vac | 7.887MN |

| Engine Length | 4.00m |

| Engine Diameter | 3.57m |

| Engine Dry Weight | 9,500kg |

| Nozzle Ratio | 36.87 |

| Thrust-to-Weight | 82 |

| Burn Time | 150s |

| Specific Impulse | 309s (SL) 338s (Vac) |

| Chamber Pressure | 245bar |

| Throttle Capability | 56%-100% |

| Engine Start | Hypergolic |

| Restart Capability | No |

| Ox to Fuel Ratio | 2.63 |

| Attitude Control | Gimbaled Engine (Pitch, Yaw, Roll) |

| Max Gimbal | 6.3deg |

| Shutdown | Commanded Shutdown |

The first and largest stage of the Zenit-3SL Rocket has an inert mass of 27,564 Kilograms. It consists of the central tank containing 236,567 Kilograms of Oxidizer, Liquid Oxygen, and the fuel tank holding 90,219 Kilograms of Rocket Propellant 1 which is rocket-grade Kerosene.

The first stage tanks are made of aluminum and features stiffeners for structural integrity. The stage is 32.9 meters long and 3.9 meters in diameter.

The first stage is equipped with one RD-171 Main Engine. This single engine is powering the entire vehicle following liftoff.

RD-171 is the most powerful rocket engine of the world. It provides 7,550 Kilonewtons (770,000 Kilograms) of Thrust at Sea Level.

The Main Engine has four combustion chambers, all fed by a single, vertically mounted turbopump, powered by two gas generators feeding hot oxidizer-rich gas to a single turbine. RD-171 provides throttle capabilities ranging from 56% to 100% of rated performance which is used to limit stress on the vehicle during ascent.

The Engine weighs 9,500 Kilograms, is 4 meters long and has a diameter of 3.57 meters. First stage attitude control is provided by gimbaling each nozzle individually by a hydraulic system by a so-called BIM hydraulic pump.

The BIM pump assembly consists of two turbopumps, one is driven by high-pressure helium and one uses Kerosene provided by the RD-171 fuel subsystem. When being powered with helium, the BIM reaches an intermediate power level which is increased to full hydraulic pressure when BIM switches to the Kerosene pump.

Guidance data is provided to the first stage by the Navigation System that is installed on the second stage. The first stage is separated from the launch vehicle 150 seconds into the mission. Zenit uses a hot-staging technique – igniting the second stage and simultaneously firing pyro bolts to have the first stage pushed away by second stage exhaust.

Second Stage

| Diameter | 3.9m |

| Length | 10.4m |

| Launch Mass/Fueled | 90,757kg |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| Fuel Mass | 22,832kg |

| Oxidizer Mass | 58,908kg |

| Propulsion | 1 RD-120 — 1 RD-8 (Vernier) |

| Engine Type | Staged Combustion |

| Propellant Feed | Turbopump |

| Total Thrust Vac | 833kN |

| Engine Length | 3.87m |

| Engine Diameter | 1.95m |

| Engine Dry Weight | 1,125kg |

| Thrust-to-Weight | 75.6 |

| Burn Time | 315s |

| Specific Impulse | 350s (Vac) |

| Chamber Pressure | 162.8bar |

| Ox to Fuel Ratio | 2.6 |

| Attitude Control | Gimbaled Engine (Pitch, Yaw, Roll) |

| Vernier Engine | RD-8 |

| Propellant | LOX/RP-1 |

| Type | Staged Combustion |

| Thrust | 78.5kN |

| Specific Impulse | 342s |

| Engine Length | 1.67m |

| Engine Diameter | 4.0m |

| Dry Weight | 380kg |

| Max Burn Time | 4,000s |

The second stage of the Zenit closely resembles the first stage design with its fuel tank located above the oxidizer tank. The stage is 10.4 meters long and 3.9 meters in diameter with an inert mass of 8,307 Kilograms.

The second stage also uses Rocket Propellant 1 and Liquid Oxygen as propellants. It holds 23,056kg of Kerosene and 59,431kg of LOX that are used during 315 seconds of powered flight before the stage is separated from the orbital unit consisting of payload and upper stage.

Stage 2 is powered by a RD-120 Main Engine and a RD-8 Vernier Thruster featuring four gimbaling nozzle that are used to provide three-axis control during the burn.

RD-120 provides 833kN (84,950kg) of thrust while the vernier engine has a nominal thrust level of 78.5kN (8,000kg). RD-120 is a single chamber engine operating at a chamber pressure of 163 bar. It is fixed and can not be moved – requiring vernier engines to provide vehicle control. The engine can be throttled back to 78%.

During the second stage burn, the Payload Fairing is jettisoned to improve ascent performance – exposing the satellite as soon as thermal and aerodynamic loads are within limits. The second stage also houses the guidance system and flight computers of the vehicle that autonomously control all aspects of the flight.

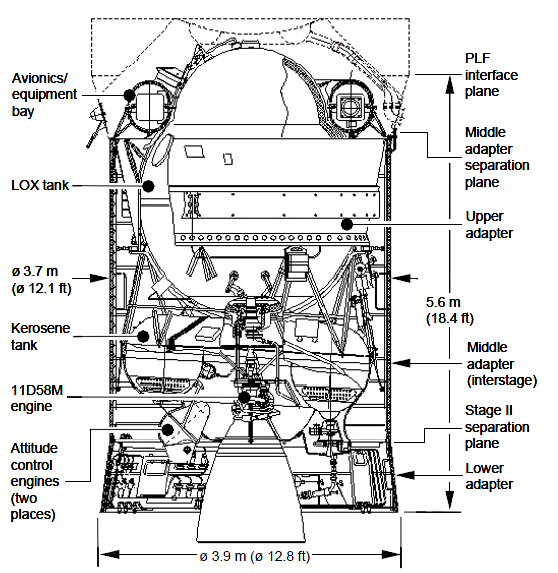

Block-DM-SL Upper Stage

| Diameter | 3.7m |

| Length | 5.6m |

| Launch Mass/Fueled | 19,711kg |

| Fuel | Rocket Propellant 1 |

| Oxidizer | Liquid Oxygen |

| Fuel Mass | 4,560kg |

| Oxidizer Mass | 11,290kg |

| Propulsion | 1 RD-58M |

| Total Thrust Vac | 83.4kN |

| Engine Length | 2.27m |

| Engine Diameter | 1.17m |

| Engine Dry Weight | 300kg |

| Thrust-to-Weight | 37 |

| Burn Time | 650s |

| Specific Impulse | 349s |

| Chamber Pressure | 77.5bar |

| Ox to Fuel Ratio | 2.48 |

| Attitude Control | Two Attitude Control Thrusters |

| 4 Nozzles on each Thruster | |

| Propellant | Hydrazine |

| Oxidizer | Nitrogen Tetroxide |

The Block DM-SLB Upper Stage represents a modification of the Block-DM Upper Stage that has first flown in 1974 and has undergone a number of major upgrades and re-designs over the decades. Originally, the Block-D originated in the Soviet Union’s lunar exploration plans. It was planned to serve as upper stage on the N1 Moon Rocket to perform burns during Earth-Moon transit.

Today, Block-D Upper Stages fly in a number of configurations, depending on the type of launch vehicle and the particular payload. Currently, Block DM-2, DM-2M, DM-03 are used on the Proton Rocket. Sea Launch uses modified Block-DM-SL Upper Stages on their Zenit 3SL launcher and Land Launch utilizes the Block DM-3SLB.

The Block-DM-SLB Upper Stage delivers payloads to a variety of orbits including low, medium and high Earth Orbits as well as supersynchronous trajectories and Earth Escape Flight Paths. Block-DM provides a precise injection capability and can support ascent missions of several hours.

The Upper Stage is built to be as small as possible to leave enough room for large payloads under the Payload Fairing. It has a dry mass of 3,861 Kilograms. Block-DM provides a precise injection capability and can support ascent missions of several hours, however nominal Sea Launch missions do not exceed 2 hours.

The Upper Stage uses Liquid Oxygen as Oxidizer and Rocket Propellant 1 as Fuel. The Propellants are stored in two tanks that are part of the core module of the Vehicle. The LOX tank has a spherical shape; the kerosene tank is toroidal, inclined to 15 degrees for better fuel extraction. In total, 15,850 Kilograms of Propellants are stored in the Block-DM’s Tanks.

The Upper stage is powered by a single RD-58M Main Engine that provides. It provides 83.4 Kilonewtons of Thrust. The engine is a pump-fed engine that provides gimbaling capability. The Main Engine can be started up to 5 Times and has a fully redundant ignition system. Attitude Control during cruise phases is provided by two Attitude Control Thrusters that are also used for ullage burns. Each attitude control engine has four nozzles that are grouped in clusters on either side of the main engine. The Attitude Control System uses Nitrogen Tetroxide and Unsymmetrical Dimethylhydrazine as propellants.

All aspects of the Block-DM Mission are controlled by the vehicle’s avionics and pre-flight commands/programs. Block-DM has a passive and active thermal control system to keep all of its systems in operating condition during longer flights. After spacecraft separation, the Upper Stage performs Collision avoidance maneuvers or performs a deorbit maneuver, depending on the flight trajectory.

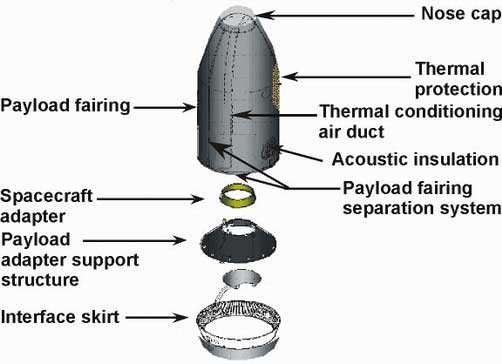

Payload Fairing

| Length | 11.39m |

| Diameter | 4.15m |

| Construction | Aluminum Honeycomb |

| Graphite/Epoxy | |

| Nosecap | Composite |

The Payload Fairing is positioned on top of the stacked vehicle and its integrated Payload. It protects the spacecraft against aerodynamic, thermal and acoustic environments that the vehicle experiences during atmospheric flight. When the launcher has left the atmosphere, the fairing is jettisoned by pyrotechnically initiated systems. The fairing is attached to the third stage and the Block-DM Upper Stage. The Zenit 3SL Payload Fairing is supplied by Boeing. The Payload Fairing has an inner diameter of 4.15m and a length of 11.39 meters. A 16-meter fairing is available for dual-payload flights.

Payload Adapter

Payload Adapters interface with the vehicle and the payload and are the only attachment point of the payload on the Launcher. They provide equipment needed for spacecraft separation and connections for communication between the Upper Stage and the Payload. The separation system can be based on either the traditional pair of pyrotechnically-initiated bolt cutters or a low-shock Clamp Band Opening Device (CBOD). Several off-the-shelf adapters are available to accommodate various payloads. Also, custom made fairings can be fitted atop the Block-DM Upper Stage to accommodate a variety off different payload requirements.

Zenit-3SL Launch System

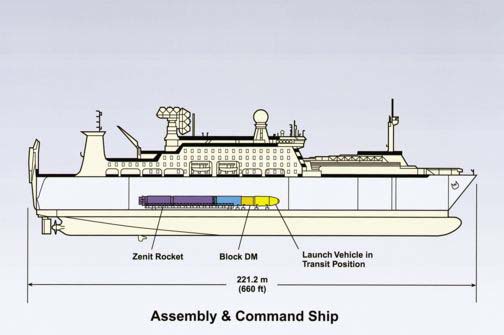

The Sea Launch Commander is used as integration and command ship for Zenit-3SL Launch Campaigns. it was built by Kvaerner Govan Ltd of Scotland. The Ship is registered in Liberia. While it is in Sea Launch’s Home Port in California, the ship acts as integration facility for the Zenit Launch Vehicle. The vessel is 200m long, 32.3m wide, with a displacement of more than 30000 tonnes and has a cruising range of 33000km. It can accommodate 240 crew members and launch support personnel. Leaving its home port, the ship is used to support the entire launch processing operation leading up to countdown and launch.

The Sea Launch Commander acts as mobile launch control central. All aspects of the Launch Countdown and vehicle ascent are monitored by launch personnel inside the launch control center. Facilities for both, US and Russian Support Teams, are in place aboard the ship with two-way translations being provided.

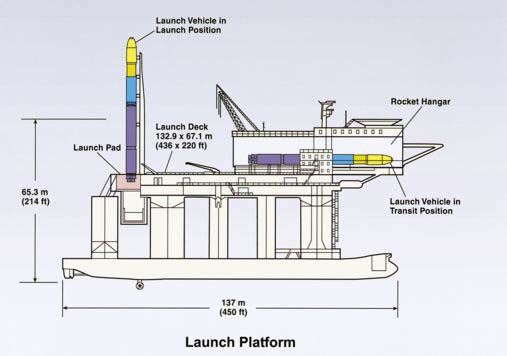

The Sea Launch Ocean Odyssey Platform is a modified oil rig, outfitted to support rocket launches. It is 133 meter long and 67 meters wide. The Platform feature a launch pad from where the rocket lifts off and an environmentally controlled hangar to store the Launch Vehicle during the transit to the launch site and for final Processing.

The vessel has accommodations for 68 crew members and launch support personnel. For Countdown and launch operations, the platform is evacuated and all crew members board the Sea Launch Commander for launch operations.

The Platform was built in 1982 and 83 as an Oil Rig and was converted to a launch platform from 1995 to 1997.