Minotaur I Launch Vehicle

The Minotaur I is an American expendable launch system operated by Orbital Sciences and the US Air Force.

The launch vehicle is based on the Minuteman II missile that are fitted with additional upper stages and Orbital avionics and control systems. It is used to launch US Government Payloads into Low Earth Orbit.

The Minuteman missile started out in its first generation as LGM-30A Minuteman I in the 1950 when development started. The first Minuteman I was test fired in 1961 and the system started deployment in 1962.

The Minuteman implemented a number of innovations including the use of solid fuel. Previous missiles and soviet ICBMs used storable liquid propellants that are corrosive in nature and reduce the shelf life of the vehicle once fueled.

Also, solid-fueled rockets could be launched within minutes of a launch order. Minuteman used a digital flight control system that provided a higher accuracy and high flexibility to the System. By 1965, 800 Minuteman I missiles were ready for use, being stationed at a number of Air Force bases throughout the US.

While Minuteman I had just started deployment, the improved Minuteman II completed its development that began in 1962. Deployment began in 1965. The Minuteman II had an increased range and throw weight and featured improved Guidance Systems to provide better accuracy for a wider range of targets. Its first stage featured design improvements to increase reliability while the second stage motor size was increased being powered by a fixed nozzle with liquid injection Thrust Vector Control.

Following the completion of Minuteman II development, the next step in the program was Minuteman III that was first deployed in 1970.

It has an improved third stage with a fluid-injected motor that provides precise vehicle control- The re-entry system was also improved to accommodate Multiple Independently Targetable Reentry Vehicles using a post-boost stage that is liquid fueled to perform trajectory adjustments and precise warhead targeting. With these improvements, Minuteman III has an increased range over the previous versions. Also, an improved flight computer was developed for the Minuteman III over the course of its deployment to improve accuracy and reliability.

Further upgrades were implemented on the vehicle over the course of its deployment. Minuteman III is still being deployed today with about 450 units in the current Air Force inventory. It is the only land-based ICBM in service in the United States. Minuteman test launches are performed regularly from Vandenberg Air Force Base, California.

Minotaur launch vehicles are operated from Space Launch Complex 8 at Vandenberg Air Force Base, Launch Pad 1 at Kodiak Launch Complex (Alaska) and Pad 0B at the Mid-Atlantic Regional Spaceport (MARS), Virginia.

Minotaur I Specifications

| Type | Minotaur I |

| Height | 19.17m |

| Diameter | 1.67m |

| Launch Mass | 36,200kg |

| Stages | 4 (+ optional HAPS) |

| Mass to LEO | 580kg |

| Mass to GTO | 331kg |

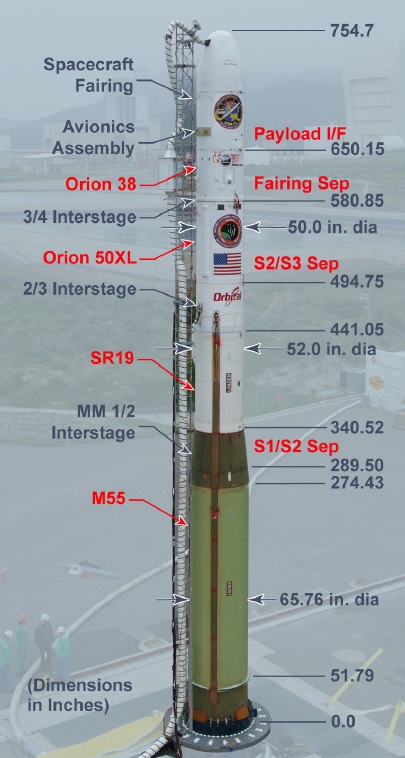

The Minotaur I orbital launch vehicle is based on the Minuteman II version, using the first and second stage of the Minuteman II, but adding two Orion stages from the Pegasus Rocket to serve as third and fourth stage with the option of adding a liquid-fueled fifth stage for precise injections.

Overall, Minotaur I stands 19.17 meters tall, 1.67 meters in diameter with a liftoff mass of 36,200 Kilograms. The launch vehicle can deliver payloads of up to 580 Kilograms into Low Earth Orbit and 331 Kilograms into Sun Synchronous Orbit.

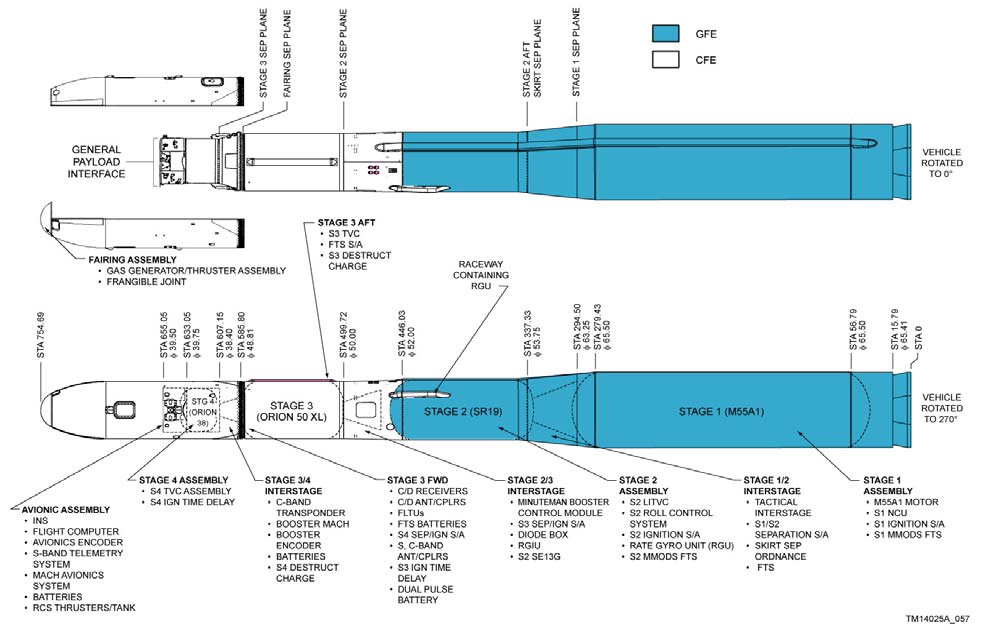

The Minotaur I launch system uses the two lower stages of the Minuteman II called M55 A1 and SR-19. Acting as third and fourth stage are the Orion 50 XL and Orion 38 stages that are also used on the Pegasus rocket. As an option, a Hydrazine Auxiliary Propulsion System can be added to serve as fifth stage to provide precise injection capability.

First Stage – M55 A1

| Type | M55 A1 |

| Length | 7.49m |

| Diameter | 1.67m |

| Inert Mass | 2,292kg |

| Launch Mass | 23,077kg |

| Propellant | Solid TP-H1011 |

| Propulsion | 4 x M55A1 |

| Thrust | 792kN |

| Specific Impulse SL | 237s |

| Specific Impulse Vac | 262s |

| Burn Time | 61.3s |

| Attitude Control | Gimbaled Nozzles |

| 1-2 Interstage | 1.68m |

Minotaur I uses an M55 A1 first stage that is 7.49 meters long and 1.67 meters in diameter with a launch mass of 23,077 Kilograms – including 20,785 Kilograms of propellant. It uses solid TP-H1011 propellant.

The stage is equipped with four nozzles that are gimbaled individually using a hydraulic system, the Nozzle Control Units, to provide three-axis control during powered flight. Total thrust on the first stage is 792 Kilonewtons – 80,760 Kilograms, creating a vacuum impulse of 262 seconds.

The Minuteman All-Ordnance Destruct System on the first stage is replaced by a Modular Mechanical Ordnance Destruct System (MMODS) Flight Termination System (FTS).

The first stage burns for 61.3 seconds and is separated from the second stage using pyrotechnic systems. At the moment of first stage burnout and separation, the second stage ignites.

The two stages are connected by a 1.68-meter interstage that houses the second stage nozzle and stage separation equipment.

Second Stage – SR-19

| Type | SR-19 |

| Length | 4.12m |

| Diameter | 1.33m |

| Inert Mass | 795kg |

| Launch Mass | 7,032kg |

| Propellant | Solid ANB-3066 |

| Thrust | 267.7kN |

| Specific Impulse Vac | 288s |

| Burn Time | 66s |

| Pitch & Yaw Control | Liquid Injection TVC |

| Roll Control | Hot Gas Roll Control Thrusters |

| Attitude Sensing | Rate Gyro Unit |

| 2-3 Interstage | 1.36m |

The second stage of the Minotaur I is called SR-19 which measures 4.12 meters in length and 1.33 meters in diameter. It has a launch mass of 7,032 Kilograms including 6,237 Kilograms of ANB-3066 propellant.

SR-19 is equipped with a single fixed nozzle with high expansion ratio providing a total thrust of 267.7 Kilonewtons – 27,300 Kilograms delivering a specific impulse of 288 seconds. Pitch and Yaw Control for the second stage is provided by a Liquid Injection Thrust Vector Control subsystem. Using a secondary fluid that is injected from the side, the Hypersonic Flow in the nozzle is changed in order to create a lateral thrust element that is precisely steered for attitude control. Roll control is provided by Hot Gas Thrusters mounted on the second stage.

Stage 2 is also equipped with a Modular Mechanical Ordnance Destruct System (MMODS) Flight Termination System (FTS).

The second stage is equipped with a separate Rate Gyro Unit to increase roll control accuracy. SR-19 burns for 66 seconds before being separated from the third stage using pyrotechnics. Between stage separation and stage three ignition, a 2.2-second delay is implemented. The 2-3 interstage is 1.36m in length.

Third Stage – Orion 50 XL

| Type | Orion 50 XL |

| Diameter | 1.28m |

| Length | 3.07m |

| Inert Mass | 391kg |

| Launch Mass | 4,306kg |

| Propellant | Solid QDL-1 (HTPB) |

| Propellant Mass | 3,915kg |

| Guidance | Closed Loop PEG |

| Max Thrust | 194.4kN |

| Avg Thrust | 158kN |

| Impulse | 289s |

| Nozzle Diameter | 861mm |

| Burn Time | 71sec |

| Average Pressure | 70.3bar |

| Attitude control | Electromechanical TVC |

| Cold Gas Reaction Control System |

The third stage of the Minotaur I rocket is an Orion 50 XL manufactured by Alliant Techsystems, ATK.

It is 3.07 meters long and 1.28 meters in diameter with a launch mass of 4,306 Kilograms. The motor is loaded with 3,915 Kilograms of QDL-1 HTPB-based solid propellant operating at a pressure of 70 bar.

Orion 50 XL provides a maximum thrust of 194.4 Kilonewtons and an average thrust of 158 Kilonewtons.

The third stage is equipped with a high-expansion nozzle for operation in vacuum.

The nozzle is gimbaled using an electromechanical Thrust Vector Control System for pitch and yaw control. A Nitrogen Cold Gas Attitude Control System is used for roll control and attitude control during coast phases. Orion 50 XL has a burn time of 71 seconds.

Between the Orion 50 XL burn and the fourth stage burn, a mission specific coast phase is implemented for orbit circularization/adjustment using the 4th stage.

| Type | Orion 38 |

| Diameter | 0.97m |

| Length | 1.34m |

| Inert Mass | 102.1kg |

| Launch Mass | 872.3kg |

| Propellant | Solid QDL-1 (HTPB) |

| Propellant Mass | 770.2kg |

| Guidance | Closed Loop PEG |

| Max Thrust | 36.9kN |

| Avg Thrust | 32.7kN |

| Impulse | 287s |

| Nozzle Diameter | 526mm |

| Burn Time | 66.8s |

| Average Pressure | 45.5bar |

| Attitude control | Electromechanical TVC +/-5° |

| Cold Gas Reaction Control System |

4th Stage – Orion 38

Serving as a fourth stage on Minotaur I is an ATK Orion 38 solid rocket motor which measures 1.34 meters in length and 0.97 meters in diameter.

It weighs 872.3 Kilograms when loaded with 770.2 Kilograms of QDL-1 propellant. Orion 38 operates at a pressure of 45.5 bar to create an average thrust of 32.7 Kilonewtons, peaking at 36.9 Kilonewtons.

It also uses an electromechanical Thrust Vector Control System to gimbal the engine nozzle by up to 5 degrees for pitch and yaw control.

Roll control during burns and attitude control during coast phases and for spacecraft separation is provided by a Nitrogen Cold Gas Attitude Control System.

The fourth stage has a burn time of 66.8 seconds that is followed by a coast phase and re-orientation for spacecraft separation.

Optional 5th Stage – HAPS

| Type | HAPS |

| Diameter | 0.97m |

| Length | 0.30m |

| Propellant | Hydrazine |

| Propellant Mass | 72kg |

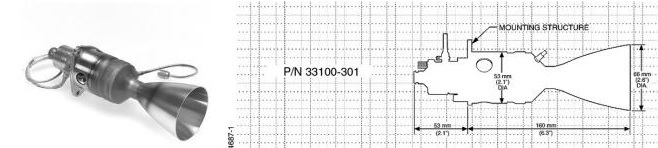

| Propulsion | 3 x MR-107 |

| Catalyst | LCH227/202 |

| MR-107 Thrust | 109 – 296N (222N nominal) |

| Mass | 740g |

| Length | 22cm |

| Diameter | 6.6cm |

| Prop Feed Pressure | 8.2 – 27.8bar |

| Chamber Pressure | 4.2 – 11.2bar |

| Specific Impulse | 229 – 232kg |

| Flow Rate | 49 – 131 g/s |

| Expansion Ratio | 20.7 |

| Burn Time | 131 + 110s (2 Burns) |

| Attitude Control | Cold Gas RCS (N2) |

Minotaur I can be outfitted with a HAPS (Hydrazine Auxiliary Propulsion System) to act as fifth stage for precise injections. It is a compact structure with a diameter of 97 centimeters and a length of about 0.3 meters. It is equipped with two spherical tanks holding Hydrazine monopropellant. Each tank holds 36 Kilograms of propellant. HAPS is equipped with a total of three MR-107N thrusters (Super HAPS uses 12 engines). Each of these engines provides a nominal thrust of 222 Newtons with a throttle capability of 109 to 296 Newtons. With the three engines at nominal throttle, HAPS has a total thrust of 666 Newtons – 68 Kilogram-force.

MR-107N operates at a propellant feed pressure of 8.2 to 27.8 bar and a chamber pressure of 4.2 to 11.2 bar to create a specific impulse of 229 to 232 seconds. The engine ingests 49 to 131 grams of fuel per second depending on the thrust setting. It has a expansion ratio of 20.7. MR-107N weighs 740 grams, measuring 22 centimeters in length and 6.6 centimeters in diameter. It uses a Moog Single Seat Valve.

Usually, HAPS performs two burns that are separated by a coast phase of about half an orbit to allow HAPS to perform a precise insertion and refine the vehicle’s orbit to match the target parameters.

HAPS is equipped with a Cold Gas Attitude Control System for three-axis control. Differential firings of the three engines can also be used for attitude maneuvers during propulsive flight phases.

Avionics & Guidance System

Minotaur I implements a Common Avionics Assembly that is used across the Minotaur family. The CAA is a ring structure that is mounted on the upper stage of the vehicle offering space for the various avionics boxes that comprise the assembly.

The Central Flight Computer of the Minotaur is based on Orbital’ s Modular Avionics Control Hardware (MACH) that provides power transfer, data acquisition, booster interfaces, and ordnance initiation. Up to 10 MACH devices can be combined to satisfy mission requirements. Minotaur’ flight computer uses a 32-bit multiprocessor architecture and a RS-422 serial bus for data connections to avionics and payload systems.

Additionally, the avionics assembly includes the Booster MACH, the Booster Control Module that provides actuator commands to the Thrust Vector Control Systems of the lower stages, the S- and C-Band Communications System that is used for telemetry downlink, Flight Termination System receivers and equipment, a GPS beacon and a vehicle encoder.

Minotaur I uses an improved telemetry system for real time data downlink up to 2Mbps with channels reserved for payload use.

Also mounted on the avionics ring is the Attitude Control System of the launcher which is a cold gas system using pressurized Nitrogen. The attitude control system is used for roll control during the 3rd, 4th and HAPS stage burns as well as three-axis control during coast phases and the Contamination and Collision avoidance maneuver.

The Common Avionics Assembly gathers navigation data using an inertial platform that feeds the digital autopilot of the vehicle. The three-axis autopilot is programmed to fly a pre-programmed attitude profile during Stages 1 and 2 flight and gather navigation data which is then used to optimize the trajectory during the Stage 3 and 4 (& HAPS) burns.

The two upper stages use a pre-defined set of parameters for their target trajectory which they use to modify their flight profile based on actual achieved trajectory by the lower stages.

The Orion 50 XL and Orion 38 stages use energy management to achieve the insertion trajectory. After the final boost phase, the three-axis cold-gas attitude control system is used to orient the vehicle for spacecraft separation, contamination and collision avoidance and downrange downlink maneuvers.

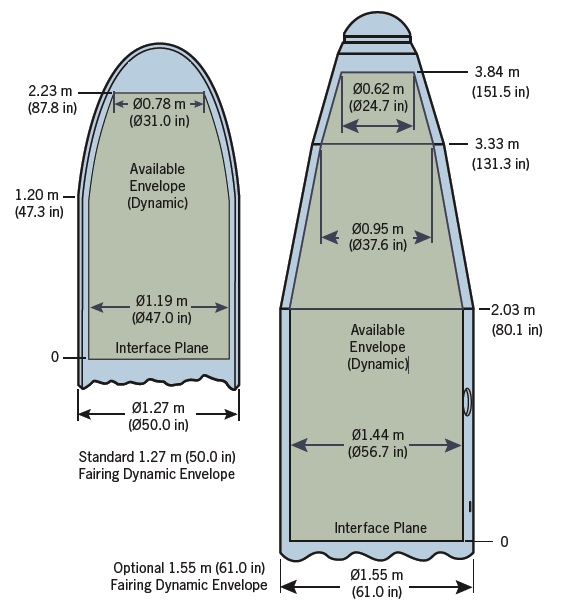

Payload Fairing

| Type I | Pegasus Fairing |

| Length | 3.78m |

| Diameter | 1.27m |

| Mass | 300kg |

| Structure | Composite Shell Halves |

| Nose Cap | |

| Type I | Stretched Fairing |

| Length | 6.1m |

| Diameter | 1.55m |

Minotaur I uses the standard Pegasus Payload Fairing. It consists of two graphite composite shell halves, a nose cap attached to one of the halves and a separation system. Each shell consists of a cylindrical section and an ogive section. The fairing is 3.8 meters long and 1.27 meters in diameter. It accommodates the Orion 38 Stage, the payload adapter and the payload itself.

The two fairing halves are joined with a base frangible joint, two titanium straps with tensioning bolts along the cylinder and a retention bolt in the nose. A cork and Room Temperature Vulcanizing (RTV) Thermal Protection System (TPS) is applied to the inside of the fairing to maintain thermal requirements of the payloads.

The Payload Fairing is separated using pyrotechnic bolt cutters that cut the bolts of the titanium straps, the retention bolt in the nose is released by a pyrotechnic separation nut. The base of the fairing is separated using a low-contamination frangible separation system. The ordnance initiations are sequence for proper separation dynamics. A hot gas generator inside the fairing is also activated at separations to pressurize two piston-driven pushers that force the two fairing halves apart so that the two halves of the fairing can rotate outboard on two hinges installed on the vehicle in order to ensure the appropriate clearances during the separation event.

To accommodate larger payloads, Minotaur I can be outfitted with a 1.55-meter diameter fairing that is 6.1 meters long featuring a similar design, but coming at the cost of launch vehicle performance.

Payload Adapters

Minotaur can support a number of Payload Adapter Modules including off-the-shelf adapters and custom built devices. Payload Adapters interface with the launch vehicle and the payload and are the only attachment point of the payload on the Launcher. They provide equipment needed for spacecraft separation and connections for communications between the Upper Stage and the Payload.

A typical PAM consists of a Payload Adapter Fitting that is connected to the upper stage, a payload cone and a separation system. Minotaur can facilitate Orbital-built as well as Planetary Systems and RUAG Space payload attach systems.

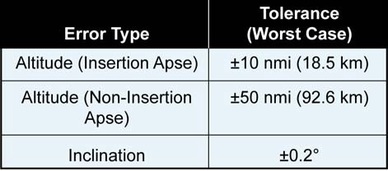

Minotaur I Injection Accuracy